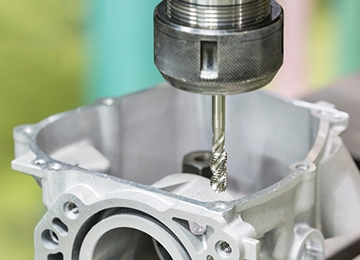

Aluminum die-casting is a kind of metal aluminum or aluminum alloy as the main raw material for pressure-casting parts. Because aluminum and aluminum alloy have excellent thermal conductivity, small specific gravity and high workability; thus aluminum die-casting is widely used in automobiles Manufacturing, internal combustion engine production, motorcycle manufacturing, electric motor manufacturing, oil pump manufacturing, transmission machinery manufacturing, precision instruments, landscaping, power construction, architectural decoration and other industries. As an enterprise with rich industry experience and advanced manufacturing technology, Suzhou Jincheng Precision Casting will talk about the application and prospects of aluminum die castings in the automobile manufacturing industry. First of all, in the past 20 years, the global energy problem has become more and more serious, which makes reducing the weight of vehicles and reducing fuel consumption become the key to competition among major automobile companies. According to data analysis and statistics, for every 100kg reduction in car weight, the combustible line distance per liter of gasoline increases by 4km; for every 1% reduction in car weight, fuel consumption drops by 0.6% to 1%. Aluminum has the characteristics of low density, good corrosion resistance, and excellent plasticity. It is suitable for casting, forging and stamping processes, and is most suitable for the die-casting process of auto parts production. In terms of production cost, part quality, and material utilization, aluminum alloy has become an indispensable and important material for automobile production. Some data show that the use of aluminum alloy instead of steel structure can reduce the weight of the car by 28% to 42%, the manufacturing of wheel hubs can reduce by 35% to 40%, and the manufacturing of engine technology can reduce by 25% to 30%. Therefore, it is said that aluminum alloy is lighter than the car. Quantification and environmental protection, energy saving, speed increase, and transportation efficiency are one of the important ways. At present, the United States, Japan, and Germany are the homes that use the most aluminum alloys in automobiles. For example, Volkswagen in Germany and Toyota in Japan use 80% of aluminum alloy for bodywork. Except for the aluminum alloy used by Shanghai Santana, FAW Audi and Jetta (all of which are imported production lines), my country’s automobiles have more red flags, about 80-100kg. Therefore, research and development of aluminum alloy cars is now very necessary.

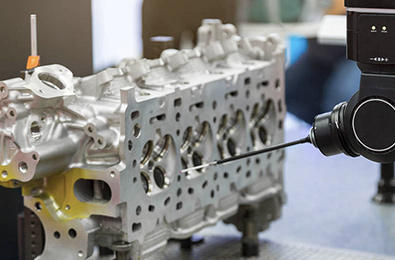

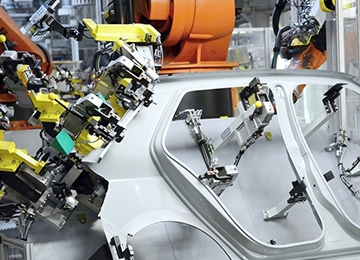

At present, the application of aluminum die-casting parts in automobiles mainly includes the following categories: 1. Aluminum alloy for engines. Since aluminum alloy for automobile engines is the most lightweight, all major automobile manufacturers in the world have carried out engine aluminization. In the research and development of materials, many foreign medical companies have adopted all-aluminum engine blocks and engine heads. 2. Aluminum alloy wheels have gradually replaced steel wheels because of their light weight, good heat dissipation, and good appearance. According to data surveys, global aluminum alloy automobile wheels have grown at an annual growth rate of 8%. 3. Deformed aluminum alloys are mainly used to manufacture decorative parts such as car doors, luggage compartment panels, bumpers, engine hoods, wheel spokes, wheel hub covers, anti-lock braking systems and dashboards. It is characterized by light weight, high strength, good crack resistance, and excellent molding. At present, the production volume of my country’s automobile manufacturing industry has jumped to the fourth place in the world, only lagging behind the three developed countries of the United States, Japan, and Germany. However, we are still lagging behind in the technology of aluminizing body. At present, the use of aluminum in automobiles in developed countries has reached the level of aluminization rate of 12%, while the aluminization rate in my country is only less than 5%. The gap is still very obvious. Therefore, the aluminum die-casting technology in my country’s automobile market The development prospects are very broad.